Ijraset Journal For Research in Applied Science and Engineering Technology

- Home / Ijraset

- On This Page

- Abstract

- Introduction

- Conclusion

- References

- Copyright

An Experimental Investigation on Self-Healing Concrete Made of Bacteria with Varying Doses

Authors: N. Venu Laxmi Durga , Kothoju Sai Baba

DOI Link: https://doi.org/10.22214/ijraset.2024.58558

Certificate: View Certificate

Abstract

The employment of carbonate-producing bacteria as a new approach to enhance the qualities of concrete has attracted a lot of interest since it is thought to be innocuous to the environment, natural, and maybe advantageous. This is a result of the favorable implications attached to these traits. The use of microbially induced carbonate precipitation as a remedy for several problems affecting concrete, such as fracture healing, reduction and change of porosity and permeability, and more, has been the subject of much investigation. Concrete crack healing is one of the topics that have been researched. Additionally, it has been shown that the procedure of bacterial carbonate precipitation, also known as bio deposition, contributes to the development of concrete\'s compressive strength. There has not yet been a thorough investigation of the research relating to the appropriate bacterial solution dose and its effect on concrete durability. This might occur as a result of the project not receiving enough time to complete it. As a result, it has been decided that an investigation will be conducted in order to determine the proper quantities of bacterial solution required for concrete. To do this, several concrete cube samples will be made using varying amounts of bacterial solution, such as 15 ml, 30 ml, 45 ml, 60 ml, and 75 ml, respectively. These quantities will be added to the appropriate moulds. This will allow you to determine the proper dosage of the bacterial solution to employ. In order to determine the optimal dosage that should be used, these various samples are also put through a battery of tests using a variety of laboratory techniques, such as the properties of materials, slump cone test, a compressive strength testing machine, an ultrasonic pulse velocity test, plate count cells, and scanning electron microscopes, Rapid Chloride Penetration Test (RCPT), Acid attack test.

Introduction

I. INTRODUCTION

Carbonate-producing bacteria have attracted lots of interest as a promising, natural, environmentally friendly novel technique to improvement of concrete characteristics. Considerable research has been conducted on utilizing microbial-induced (Dilja Rose Joseph, Life John 2017)[10] carbonate precipitation to mitigate several concrete problems such as crack repair, reduction and modification of porosity, and permeability. Furthermore, bacterial carbonate precipitation (bio deposition) has shown positive influences on compressive strength improvement of concrete and also, it also reduces water absorption and carbonation of concrete as an alternative surface treatment (Pipat Termkhajornkit et.al. 2009) [1]. As part of metabolism, some bacteria (S. Sunil Pratap Reddy et.al. 2010) [2] (C.C. Gavimath et.al. 2012) [4] produces enzyme urea which catalyzes the hydrolysis of urea to generate carbonate ions without an associated production of protons which leads to CaCO3 precipitation in presence of calcium ions. Therefore, bacteria cells not only provide a nucleation site for CaCO3 precipitation due to their negatively charged cell walls, but also create an alkaline environment inducing further growth of CaCO3 crystals. One ml of urea is hydrolyzed intra-cellularly to 1 ml of ammonia and 1 ml of carbonate, which is presented in Eq. (1). According to Eq. (2), carbonate hydrolyzes to ammonia and carbonic acid.Eqs. (3) and (4) demonstrate former products subsequently equilibrate in water to form bicarbonate, ammonium, and hydroxide ions. The latter causes pH increase resulting in the formation of carbonate ions [Eq. (5)], which in the presence of soluble calcium ions precipitate as CaCO3 [Eq. (6)]. Eq. (7) is the overall reaction, which demonstrates that ammonium and calcium carbonate are the products of added urea and calcium to the system

A. Aim of the Work

- Bacteria belonging to the bacillus family should be mixed in with the bacteria that are already present in order to produce bacterial concrete (Bacillus subtilis).

- to establish the ideal number of bacteria that should be employed in the manufacturing of bacterial concrete. The goal of this research is to achieve this.

- The method of serial dilution was used in order to determine the total number of viable bacterial cells.

- An ultrasonic pulse velocity test will be used for the purpose of determining whether or not there are openings.

- We use SEM to ascertain whether or not there are voids inside the internal structure of the concrete being examined.

- Investigate bacterial activity from the point of view of chemistry.

- Investigate how the change affects the characteristics of the concrete, such as how its compressive strength and permeability are affected by the transformation.

II. MATERIALS

- Cement: For the sake of this specific experiment, Portland cement of the standard 53 grade kind, which can be procured with relative ease, was used. The cement that was utilised was subjected to a battery of tests in accordance with IS: 4031-1988 to assess its different properties. The findings indicated that the cement was compliant with the various criteria of IS: 12269-1987 and had a specific gravity of 3.15. The examinations were carried out in accordance with the recommendations that were included in IS: 4031-1988.

- Fine Aggregate: In the course of our investigation, we made use of GODAVARI sand, which provided conclusive evidence that zone III is relevant in light of IS-383's requirements. It was established that the specific gravity of sand is 2.386, giving it a value.

- Coarse Aggregate: The component of concrete known as the coarse aggregate is the component that is both the most permeable and the most robust of all of the components that make up concrete. It is possible that drying shrinkage and other dimensional changes brought about by the passage of moisture may be decreased to a level that is more controllable if coarse aggregate is used. During the course of our experiment, we made use of an aggregate that was able to get through a 20mm IS-Sieve but was still able to be captured on a 12.5mm sieve. This allowed us to have the best of both worlds. Because of this, we were able to enjoy the benefits of both settings. After doing more research, it was discovered that the aggregate had a specific gravity of 2.994.

- Bacteria: Bacillus Subtilis as shown in figure.1 is selected because it produces Calcium Carbonate which is main component for cement.

Table 1: Physical Properties of Cement

|

Sr. No. |

Particulars |

cement |

|

1 |

Grade |

53 |

|

2 |

Specific gravity |

3.15 |

|

3 |

Standard consisteny % |

32 |

|

4 |

Fineness |

3 |

|

5 |

Initial setting time |

30 min |

|

6 |

Final setting time |

600 min |

Table 2: Properties of Fine Aggregate.

|

Sr. No. |

Particulars |

cement |

|

1 |

Specific gravity |

2.386 |

|

2 |

Fineness modulus |

3.06 |

|

3 |

Bulk density |

1451 kg/m3 |

|

4 |

Voids ratio |

0.644 |

Table 3: Properties of Coarse Aggregate

|

Sr. No. |

Particulars |

cement |

|

1 |

Specific gravity |

2.994 |

|

2 |

Fineness modulus |

7.17 |

|

3 |

Bulk density |

1594 kg/m3 |

|

4 |

Voids ratio |

0.878 |

III. METHODOLOGY

The mix ratio of M30 is 1:1.97:2.96 having the following different mixes confirming with IS: 10262-2009 [12]

Conventional Concrete of grade M 30 Concrete with 15 ml bacterial solution Concrete with 30 ml bacterial solution Concrete with 45 ml bacterial solution Concrete with 60 ml bacterial solution Concrete with 75 ml bacterial solution.

A. Cultivation of Bacteria

Bacillus Subtilis, a pure bacteria culture, is kept on nutrient agar slants. On nutrient agar slants, it develops irregular dry white colonies. Two colonies of bacteria (Harshali J et.al 2016) are seeded into 350 mL of nutrient in a 500 mL conical flask as shown in figure 2 and incubated at 37 degrees Celsius using a 150 rpm orbital shaker incubator. Peptone, NaCl, and yeast extract are the main ingredients in the bacterial culture medium.

B. Slump Cone Test

The container is filled with bacterial concrete in three layers, whose workability is to be examined, and the metal plate, which serves as the base, is placed on a smooth surface. A standard 16 mm (5/8 in) diameter steel rod, rounded at the end, is used to tamper each layer 25 times. The top surface of the mould is struck off (levelled with mould top aperture) by screening and rolling motion of the tamping rod once the microbiological concrete is entir filled. The Moulds remained securely against their base throughout the procedure, preventing them from moving owing to the pouring of concrete through handles or foot-rests. The cone is gently and carefully removed vertically when the filling has been done and the concrete has been levelled, unsupported bacterial concrete will now slump as shown in figure 3.2. The slump is measured by inserting the cone next to the slumped concrete and tamping the area with the tamping rod. With scale, the height of concrete is determined to be 110mm for conventional concrete and 50mm for bacterial concrete, indicating a decrease in height to that of Moulds.

C. Compressive Strength Test

After with drawing the specimen from the water for the required curing time, the surplus water was scraped from the surface. The bearing surface of the testing machine needs to be cleaned. (M. Manjunath et.al 2014) [7] The numerous sample specimens were placed in the machine one after the other, with the load applied to the opposing sides of the cube cast. The specimen is perfectly placed as shown in figure 3.3on the machine's base plate. The force is delivered gradually, without shock, and at a rate of 5.2 KN/sec until the specimen fails. The maximum load was recorded, as well as any unexpected characteristics in the type of failure. Concrete cubes in the CTM machine, both before and after crushing. Each bacterial concrete sample's readings 15ml, 30ml, 45ml, 60ml and 75ml were taken each time after curing interval of 7days, 14 days and 28 days.

D. Plate Count TEST

An Experiment using the plate count technique was carried out in order to ascertain the overall number of viable cells that are present in a culture of bacteria. This was accomplished by counting the number of plates used in the experiment. This approach is used to determine the number of cells that are capable of reproducing under certain circumstances in order to offer an answer to the problem that the research was attempting to investigate.

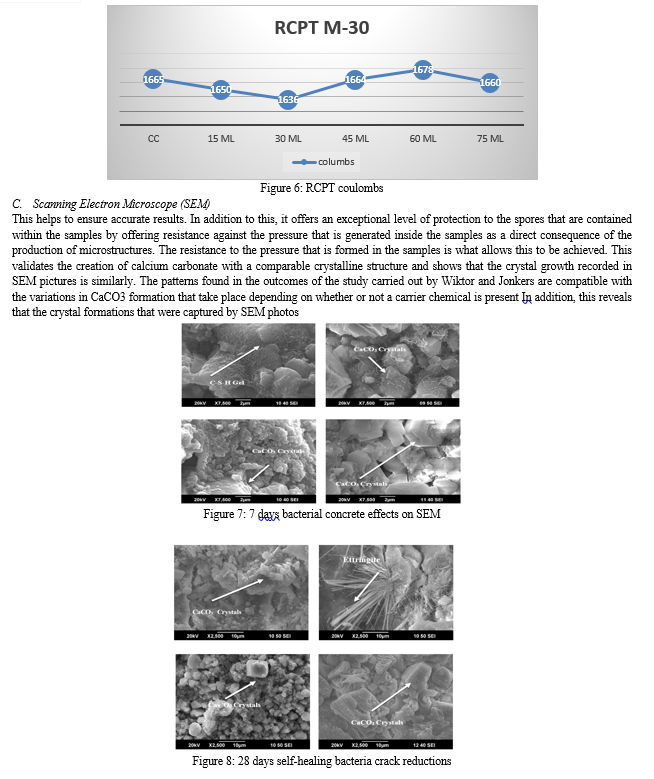

E. Scanning Electron Microscope (SEM)

An investigation of the calcium carbonate crystals that had been deposited was carried out with the use of a scanning electron microscope. The shape of the crystals as well as their mineralogical make-up were the primary focuses of this investigation (SEM). In order to create the SEM micrographs, a Jeol JSM 5600 LV type Philips XL 30 that was connected to an EDX unit was used. The voltage that was used to accelerate was changed to 30 kilovolts. The resolution was changed to W, and the magnification was increased as high as 400,000 times its initial size (3.5 nm). After having a layer of carbon applied to their surface, the samples were subsequently given a covering of gold to cover their exposed areas.

F. Rapid Chloride Penetration Test (RCPT)

The RCPT is carried out by keeping track of the quantity of electrical current that flows through a sample that is 6 hours long and has aspects of 50 millimetres in thickness and 100 millimetres in circumference. The sample also has dimensions of 50 millimetres in thickness and 100 millimetres in circumference. In most laboratories, the sample is prepared as a slice that is taken from the centre of a cylinder. The voltage between the two ends of the sample is kept at a constant direct current of sixty volts during the whole of the test. The first lead is immersed in a solution containing 3.0 percent sodium chloride (NaCl), and the second lead is immersed in a solution containing 0.3 M sodium hydroxide (NoaH). The charge that is permitted to travel through the sample is used to offer a qualitative evaluation of the permeability of the concrete, as stated in the Table. This is done using the charge that is allowed to go through the sample.

IV. RESULTS AND DISCUSSIONS

A. Compressive Strength Test results

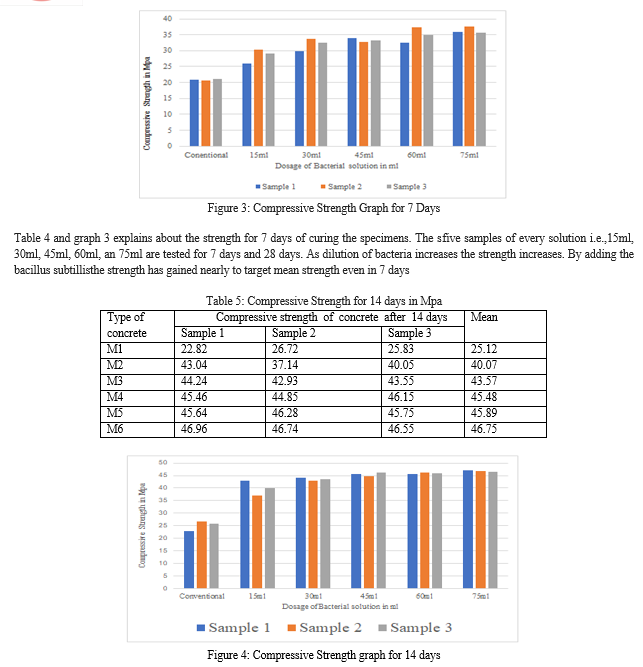

Compressive strength of concrete cube was carried out confirming IS: 516-1959 after curing period of 7,14,28 days. The results so obtained are tabulated below with their respective graph.

Table 4: Compressive Strength results for 7 days in Mpa

|

Type of concrete |

Compressive strength of concrete after 7days |

Mean |

||

|

Sample 1 |

Sample 2 |

Sample 3 |

||

|

M1 |

20.86 |

20.70 |

21.16 |

20.90 |

|

M2 |

25.89 |

30.20 |

29.17 |

28.42 |

|

M3 |

29.76 |

33.65 |

32.48 |

31.96 |

|

M4 |

33.84 |

32.74 |

33.27 |

33.28 |

|

M5 |

32.58 |

37.27 |

34.85 |

34.89 |

|

M6 |

35.82 |

37.67 |

35.70 |

36.39 |

Table 5 and graph 4 describes about the bacterial concrete specimens compressive strength after 28 days of curing at room temperature. The increment of the solution increases the strength of concrete. But after 45ml solution the strength decreases gradually because of the bacterial content which are effecting the strength characteristics are increased graph 5 explains about the strength for 7 days of curing the specimens. The five samples of every solution i.e.,15ml, 30ml, 45ml, 60ml, an 75ml are tested for 7 days and 28 days. As dilution of bacteria increases the strength increases. By adding the bacillus subtillis the strength has gained nearly to target mean strength even in 7 days

Conclusion

The highlight the production processes that have been investigated and the performance that have been measure on bacterial self-healing concrete. In conclusion, any type of bacteria with ability to metabolically convert calcium source into calcium carbonate can be used in producing autogenous healing concrete. It is important to provide protection to bacteria in concrete to sustain the self-healing ability throughout the life span of concrete. Bacterial concrete has lower strength compared to conventional concrete about the same composition. However, bacterial concrete able to fully repair visible crack autogenously compared to conventional concrete. 1) Incorporating \"Bacillus Subtilis\" at the correct concentration results in concrete more strength. 2) The increasing of bacterial solution, the strength increases up to 60 ml and then strength decreases. 3) As compared with conventional concrete, the concrete specimen containing 45ml solution of bacteria increases 25% strength considering the average of three samples after 28 days of curing. 4) The concrete containing the 45ml bacterial solution is good to use for crack repairing purposes. 5) Ultrasonic pulse velocity probing in direct method maximum in 30 ml of bacteria used velocity is increased. 6) The maximum bacterial plate count in 45 ml 7) Maximum Rapid Chloride Penetration values are 60 ml dosage of bacterial concrete. 8) The resistance of concrete against the assault of acid is noticeably higher than that of regular, typical concrete. It has been shown that bacterial concrete with 60 ml as a substitute offers significantly improved resistance to acid assault. 9) A crack in concrete that is between one and forty-five micrometres wide may be healed in a period of thirty days, demonstrating that there is a viable cure for microcracks. 10) Oxygen is the agent that may cause corrosion. However, since bacteria consume oxygen, the rate of corrosion can be lowered while the bacteria continue to thrive. 11) The formation of cracks will be healed at an earlier stage than was originally envisaged, which will result in an increase in the service life of the structure beyond its projected life.

References

[1] Pipat Termkhajornkit, Toyoharu Nawa, Yoichi Yamashiro, Toshiki Saito Self- healing ability of fly ash cement systems. (2009). [2] S. Sunil Pratap Reddy, M.V. Seshagiri Rao, P. Aparna and Ch. Shashikala Performance of standard grade bacterial concrete, Asian Journal of Civil Engineering Vol.11, No.1 (2010). [3] Kaustubh Dasgupta, A. S. Sajith Proceedings of SECON\'19: Structural Engineering and Construction Management: 46 (Lecture Notes in Civil Engineering) [4] C.C. Gavimath, B.M. Mali, J.D. Mallpur, A.B.Patil Potential application of bacteria to improve the strength of cement concrete. BioIT Journal Vol 3, Issue 1, 2012. [5] Navneet Chahal, Rafat Siddique, Anita Rajor Influence of bacteria on the compressive strength, water absorption and rapid chloride permeability of fly ash concrete. [6] Mayur Shantilal Vekariya, Prof. Jayesh Kumar Pitroda Bacterial Concrete: New Era for Construction Industry. IJETT- Vol 4 Issue 9- Sep 2013 [7] Prof. M. Manjunath, Prof. Santosh A. Kadapure, Ashwin Kumar A. Kalaje An experimental investigation on the strength and durability aspects of bacterialconcrete with fly ash. ISSN 2224-5790 ISSN 2225-0514 Vol. 6, No.6, 2014. [8] Snajukta Sahoo, B.B. Das, A.K. Rath and B.B. Kar Acid, Alkali and Chloride resistance high volume fly ash concrete. Vol 8 (19) August 2015. [9] Harshali J., Mitali S., Neha A., Pragati B. Bio concrete and bacteria based self- healing concrete. IJRET eISSN: 2319-1163 pISSN: 2321-7308 Vol.05 Issue: 05 May 2016. [10] Dilja Rose Joseph, Life John Strength assement of fly ash modified microbial concrete. Vol.7 Issue No.4 April 2017. [11] Etaveni Madhavi, S.B. Sankar Rao, Gaddam Swarna Malika Strength properties ofa bacterial cement mortar when cement partially replaced with GGBS. Vol. 3, Issue-2, 2017. [12] IS 10262: 2009, Concrete mixing Proportioning. [13] IS: 383-2016 “Coarse and Fine aggregates of concrete specifications”, Bureau of Indian Standards, New Delhi. [14] IS: 12269-1987 “Specifications for Ordinary Portland Cement for 53 Grade”, Bureau of Indian Standards, New Delhi. [15] IS: 516-1959 “Method of tests for strength of concrete”, Bureau of Indian Standards, New Delhi.

Copyright

Copyright © 2024 N. Venu Laxmi Durga , Kothoju Sai Baba . This is an open access article distributed under the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

Download Paper

Paper Id : IJRASET58558

Publish Date : 2024-02-22

ISSN : 2321-9653

Publisher Name : IJRASET

DOI Link : Click Here

Submit Paper Online

Submit Paper Online